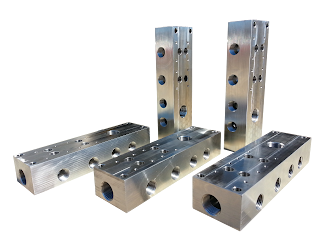

ProCam Services LLC. has worked exceptionally hard the past several years to master machining stainless steel details and stainless steel custom components for our customers. The stainless steel details shown above were exceptionally difficult because of the amount of material that needed to be removed and the +/- .001 flatness and thickness specifications required by our customer. Stainless steel can be exceptionally tricky to machine because it can be gummy, it can react strangely to cutting conditions and it will warp and bend when material is removed. We pride our selves in manufacturing the difficult stainless steel projects for our customers in a timely and cost effective manner. Some of the example pictures included with this post have difficult to machine features and/or exceptionally tight tolerances. ProCam Services LLC. has extensive experience in milling and turning a variety of grades of stainless steel in both the 300 series and 400 series. www.procamservices.com

The special brackets shown above were machined from one solid piece of 303 stainless steel with cosmetic aesthetics kept in mind because they were mounted on a prototype assembly that was displayed at a tradeshow. www.procamservices.com

The special clamps shown above were machined from 303 stainless steel…the clamps feature a tricky geometry to machine and needed special fixturing to hold them during the machining process. www.procamservices.com

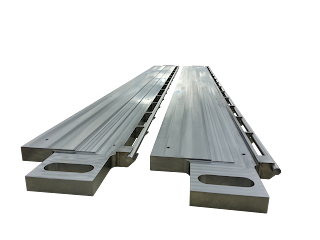

The stainless steel rails shown above were machined to thickness, flatness and straightness tolerances of .001 over 35″ of part length at ProCam Services LLC. www.procamservices.com

The 45″ long stainless steel weldments shown above feature a variety of components machined to tight tolerances on all surfaces and were welded, assembled and delivered complete to our customer. www.procamservices.com

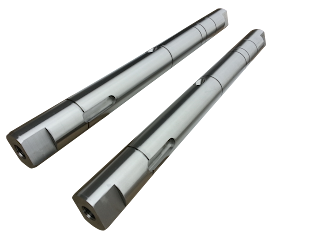

The precision stainless steel drive shafts shown above were turned and milled at ProCam Services LLC. These shafts feature many tolerances of +.000/-.001, an exceptionally long through hole, deep threading, an intersecting hole milled on a 45 degree angle, snap ring grooves, corresponding keyways machined exactly 180 degrees from each other, flats milled on both ends and the outer diameter turned down to 40mm +/- .001 over 17″ of length.

I guess this info is totally unique. precision component manufacturing

You guys out there are performing a great job. premium wordpress themes