One of the most preferred materials for CNC machining is steel. However, selecting the best option for specific applications can take time and effort, especially with such a large selection of steel alloys. To determine the most suitable steel, it is crucial to consider its machinability, hardness, allowable heat inputs, and the surface finishes it offers.

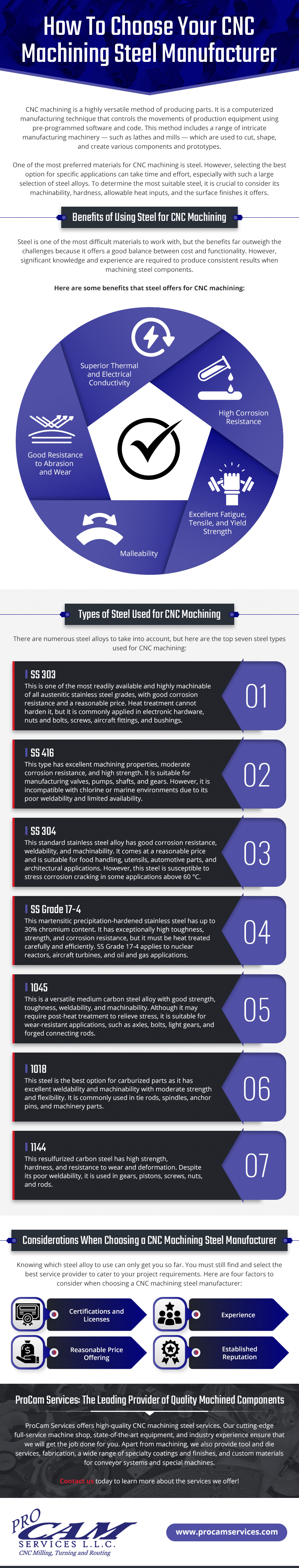

Benefits of Using Steel for CNC Machining

Steel is one of the most difficult materials to work with, but the benefits far outweigh the challenges because it offers a good balance between cost and functionality. However, significant knowledge and experience are required to produce consistent results when machining steel components.

Here are some benefits that steel offers for CNC machining:

- High corrosion resistance

- Excellent fatigue, tensile, and yield strength

- Malleability

- Good resistance to abrasion and wear

- Superior thermal and electrical conductivity

Types of Steel Used for CNC Machining

There are numerous steel alloys to take into account, but here are the top seven steel types used for CNC machining:

SS 303

This is one of the most readily available and highly machinable of all austenitic stainless steel grades, with good corrosion resistance and a reasonable price. Heat treatment cannot harden it, but it is commonly applied in electronic hardware, nuts and bolts, screws, aircraft fittings, and bushings.

SS 416

This type has excellent machining properties, moderate corrosion resistance, and high strength. It is suitable for manufacturing valves, pumps, shafts, and gears. However, it is incompatible with chlorine or marine environments due to its poor weldability and limited availability.

SS 304

This standard stainless steel alloy has good corrosion resistance, weldability, and machinability. It comes at a reasonable price and is suitable for food handling, utensils, automotive parts, and architectural applications. However, this steel is susceptible to stress corrosion cracking in some applications above 60 °C.

SS Grade 17-4

This martensitic precipitation-hardened stainless steel has up to 30% chromium content. It has exceptionally high toughness, strength, and corrosion resistance, but it must be heat treated carefully and efficiently. SS Grade 17-4 applies to nuclear reactors, aircraft turbines, and oil and gas applications.

1045

This is a versatile medium carbon steel alloy with good strength, toughness, weldability, and machinability. Although it may require post-heat treatment to relieve stress, it is suitable for wear-resistant applications, such as axles, bolts, light gears, and forged connecting rods.

1018

This steel is the best option for carburized parts as it has excellent weldability and machinability with moderate strength and flexibility. It is commonly used in tie rods, spindles, anchor pins, and machinery parts.

1144

This resulfurized carbon steel has high strength, hardness, and resistance to wear and deformation. Despite its poor weldability, it is used in gears, pistons, screws, nuts, and rods.

Considerations When Choosing a CNC Machining Steel Manufacturer

Knowing which steel alloy to use can only get you so far. You must still find and select the best service provider to cater to your project requirements. Here are four factors to consider when choosing a CNC machining steel manufacturer:

Certifications and Licenses

Precision CNC machine manufacturers are required by law to file their businesses with the state. This entails registering their business before receiving a license. Remember to look for a manufacturer with the necessary certifications and authorizations to produce high-quality products that meet your industry’s regulations.

Experience

Another effective way to find a good manufacturer is to look at their background. An experienced partner is more likely to understand your manufacturing process. Thus, they can develop customized precision CNC machines and services tailored to your needs.

Reasonable Price Offering

Prices for services provided by various manufacturers may differ. Companies that offer low-cost services may have inexperienced employees and poor service, whereas manufacturers with exorbitant fees may take advantage of you. Find a partner willing to work within your budget without compromising quality standards.

Established Reputation

The reputation of a precision CNC service provider is based on its interactions with past clients. Only work with manufacturers with overwhelmingly positive reviews that attest to their reliability and excellent customer service.

ProCam Services: The Leading Provider of Quality Machined Components

ProCam Services offers high-quality CNC machining steel services. Our cutting-edge full-service machine shop, state-of-the-art equipment, and industry experience ensure that we will get the job done for you. Apart from machining, we also provide tool and die services, fabrication, a wide range of specialty coatings and finishes, and custom materials for conveyor systems and special machines.

Contact us today to learn more about the services we offer!