Precision computer numerical control (CNC) machining is one of the most recent innovations in the manufacturing sector. It allows manufacturers to increase production speed and efficiency while reducing errors. It also enables the usage of special equipment to transform big chunks of material into more precise components. Whether you have a large or small project that requires CNC machining, choosing the right manufacturing company to partner with is crucial. You must plan your process for selecting the ideal service provider for your needs to avoid expensive and time-consuming mistakes. This article will walk you through the key factors when choosing the right CNC machining metal manufacturer for your project.

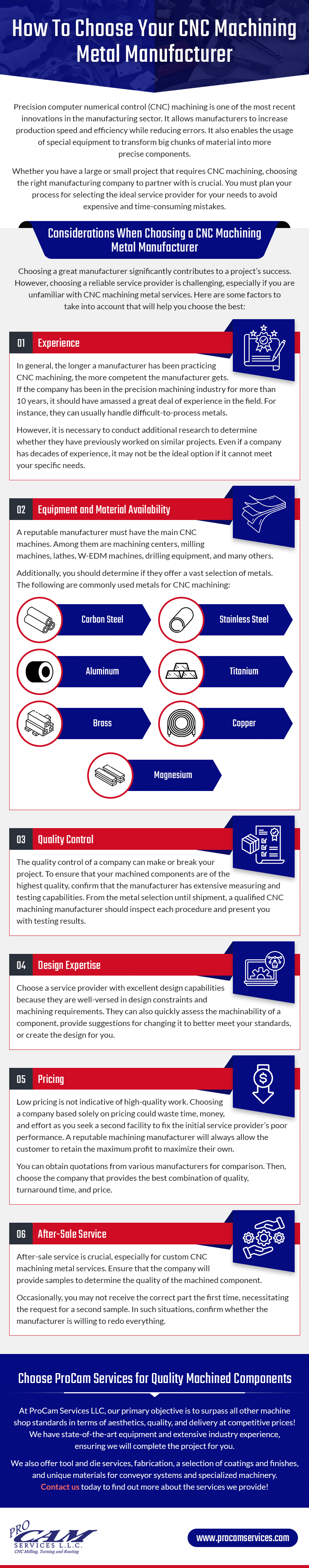

Considerations When Choosing a CNC Machining Metal Manufacturer

Choosing a great manufacturer significantly contributes to a project’s success. However, choosing a reliable service provider is challenging, especially if you are unfamiliar with CNC machining metal services. Here are some factors to take into account that will help you choose the best:

Experience

In general, the longer a manufacturer has been practicing CNC machining, the more competent the manufacturer gets. If the company has been in the precision machining industry for more than 10 years, it should have amassed a great deal of experience in the field. For instance, they can usually handle difficult-to-process metals. However, it is necessary to conduct additional research to determine whether they have previously worked on similar projects. Even if a company has decades of experience, it may not be the ideal option if it cannot meet your specific needs.

Equipment and Material Availability

A reputable manufacturer must have the main CNC machines. Among them are machining centers, milling machines, lathes, W-EDM machines, drilling equipment, and many others. Additionally, you should determine if they offer a vast selection of metals. The following are commonly used metals for CNC machining:

- Carbon steel

- Stainless steel

- Aluminum

- Titanium

- Brass

- Copper

- Magnesium

Quality Control

The quality control of a company can make or break your project. To ensure that your machined components are of the highest quality, confirm that the manufacturer has extensive measuring and testing capabilities. From the metal selection until shipment, a qualified CNC machining manufacturer should inspect each procedure and present you with testing results.

Design Expertise

Choose a service provider with excellent design capabilities because they are well-versed in design constraints and machining requirements. They can also quickly assess the machinability of a component, provide suggestions for changing it to better meet your standards, or create the design for you.

Pricing

Low pricing is not indicative of high-quality work. Choosing a company based solely on pricing could waste time, money, and effort as you seek a second facility to fix the initial service provider’s poor performance. A reputable machining manufacturer will always allow the customer to retain the maximum profit to maximize their own. You can obtain quotations from various manufacturers for comparison. Then, choose the company that provides the best combination of quality, turnaround time, and price.

After-Sale Service

After-sale service is crucial, especially for custom CNC machining metal services. Ensure that the company will provide samples to determine the quality of the machined component. Occasionally, you may not receive the correct part the first time, necessitating the request for a second sample. In such situations, confirm whether the manufacturer is willing to redo everything.

Choose ProCam Services for Quality Machined Components

At ProCam Services LLC, our primary objective is to surpass all other machine shop standards in terms of aesthetics, quality, and delivery at competitive prices! We have state-of-the-art equipment and extensive industry experience, ensuring we will complete the project for you. We also offer tool and die services, fabrication, a selection of coatings and finishes, and unique materials for conveyor systems and specialized machinery. Contact us today to find out more about the services we provide!