Machining Big Aluminum Plates at Pro-Cam Services LLC.!

Pro-Cam Services LLC. specializes in machining large aluminum plates for its customers from both 6061 and aluminum jig and fixture plate for the automation, OEM and a variety of other industries! Pro-Cam Services LLC. can machine aluminum plates as large as 80″X144″ featuring tight tolerances, drilled/tapped/reamed holes, 3D machining, complex or tricky features and most side holes! Pro-Cam Services LLC. has been machining big special fixture bases, special machine plates, special machine side walls, special gussets support beams, rails and much more for a wide variety of customers!

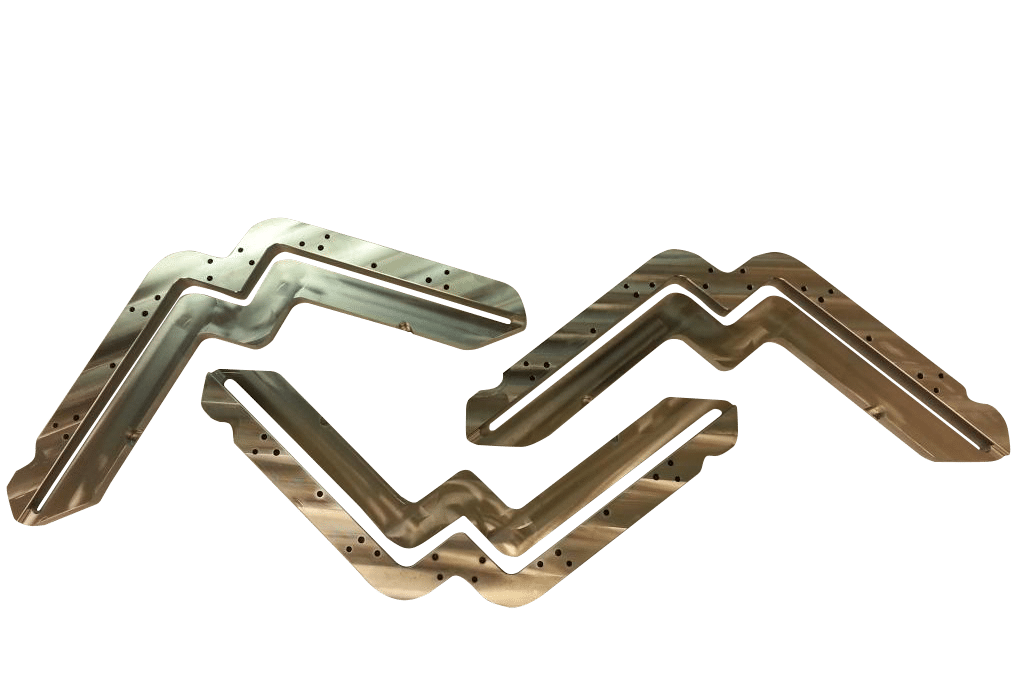

Pictured above fixture base plates machined from ATP5 ready for final inspection…than off to anodize and than off to the customer…manufactured at Pro-Cam Services LLC. for an OEM customer.

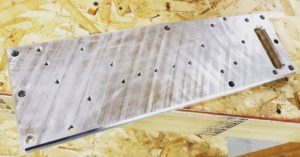

Pictured above is a platen machined on both sides from aluminum jig and fixture plate featuring tight tolerances and lots of machining… manufactured in batches of 40pc at Pro-Cam Services LLC. for an OEM customer.

Pictured above is large detail machined from a piece of 3″X38″X42″ 6061 aluminum featuring 3D machining on both sides manufactured in several different versions at Pro-Cam Services LLC. for an Automotive customer.

Pictured above is an exceptionally long detail machined from aluminum jig and fixture plate at Pro-Cam Services LLC. for an Automation customer.

Pictured above is an camera mount plate machined from aluminum jig and fixture plate at Pro-Cam Services LLC. for an Automation customer.

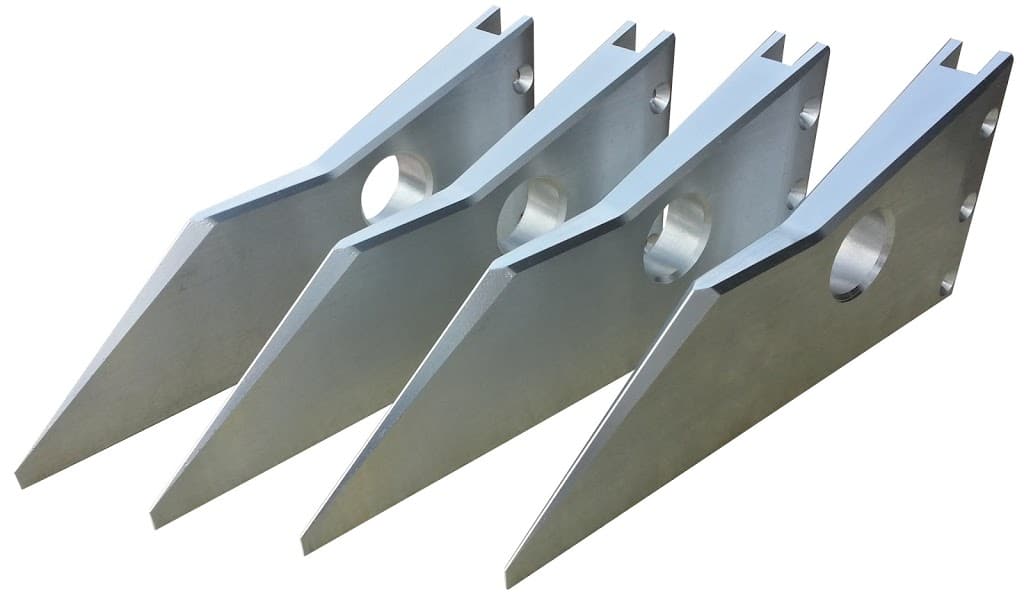

Pictured above special machine side walls machined from 1.5″ thick 6061 alum at Pro-Cam Services LLC. for an Automation customer.

One Stop Machine Shop!

Fast Track Service!

Pro-Cam Services LLC. is proud to announce and advertise a new system for getting you CNC Machined parts fast!

Fast Track Service: 1-2 Day Delivery

Fast Track Service is a special 1-2 day expedited delivery service of your machined parts and/or components. Pro-Cam Services LLC. specializes in quick-turn deliveries, rapid prototyping and helping you with your expedite or emergency projects. Our dedicated and experienced staff of machinists will work around the clock to get you your Fast Track order fast! The size and scope of your project will obviously effect the specific timing of delivery and If your parts require any special coatings and/or special outside services beyond machining extra time may need to be added to delivery. Pricing and specific delivery times will all be clearly communicated in your quotation prior to you placing your order.

Rush Service: 3-6 Day Delivery

Rush Service is a 3-6 day delivery service of your machined parts and/or components. Pro-Cam Services LLC. specializes in delivering your order fast and we are set-up and ready to handle your rush order! The size and scope of your project will obviously effect the specific timing of delivery and If your parts require any special coatings and/or special outside services beyond machining extra time may need to be added to delivery. Pricing and specific delivery times will all be clearly communicated in your quotation prior to you placing your order.

Standard Service: 7-10 Day Delivery

Standard Service is a 7-10 day delivery service of your machined parts and components. Pro-Cam Services LLC. specializes in moving your standard service projects through our shop quickly and effeciently so that you recieve them fast and on time! The size and scope of your project will obviously effect the specific timing of delivery and If your parts require any special coatings and/or special outside services beyond machining extra time may need to be added to delivery. Pricing and specific delivery times will all be clearly communicated in your quotation prior to you placing your order.

Fast Track Service is a special 1-2 day expedited delivery service of your machined parts and/or components. Pro-Cam Services LLC. specializes in quick-turn deliveries, rapid prototyping and helping you with your expedite or emergency projects. Our dedicated and experienced staff of machinists will work around the clock to get you your Fast Track order fast! The size and scope of your project will obviously effect the specific timing of delivery and If your parts require any special coatings and/or special outside services beyond machining extra time may need to be added to delivery. Pricing and specific delivery times will all be clearly communicated in your quotation prior to you placing your order.

Rush Service: 3-6 Day Delivery

Rush Service is a 3-6 day delivery service of your machined parts and/or components. Pro-Cam Services LLC. specializes in delivering your order fast and we are set-up and ready to handle your rush order! The size and scope of your project will obviously effect the specific timing of delivery and If your parts require any special coatings and/or special outside services beyond machining extra time may need to be added to delivery. Pricing and specific delivery times will all be clearly communicated in your quotation prior to you placing your order.

Standard Service: 7-10 Day Delivery

Standard Service is a 7-10 day delivery service of your machined parts and components. Pro-Cam Services LLC. specializes in moving your standard service projects through our shop quickly and effeciently so that you recieve them fast and on time! The size and scope of your project will obviously effect the specific timing of delivery and If your parts require any special coatings and/or special outside services beyond machining extra time may need to be added to delivery. Pricing and specific delivery times will all be clearly communicated in your quotation prior to you placing your order.

Precision Components

Precision components machined from a variety of materials for a variety of industries at Pro-Cam Services LLC.

We are increasing capacity!

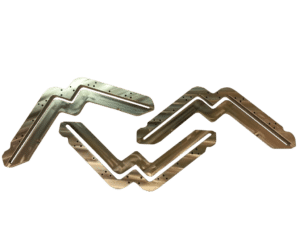

Some interesting aluminum details recently machined at Pro-Cam Services LLC.!!

Some interesting aluminum details recently machined at Pro-Cam Services LLC.

Pro-Cam Services LLC

4th-Axis & Rotary Machining Capabilities at Pro-Cam Services LLC.

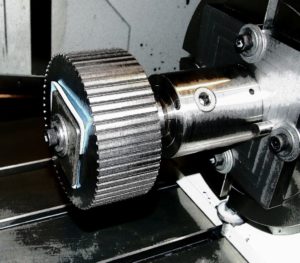

4th Axis machining involves using an indexing head that works in conjunction with a 3 Axis CNC mill. The 4th Axis is mounted into the CNC mill to be used for advanced machining operations. The 4th Axis gives the mill an A-Axis that allows the operator to machine multiple sides of a part without having to stop to rotate or readjust the work piece.

Pro-Cam Services LLC. has three mills with either 4th axis or rotary machining capabilities. The 4th-axis and rotary capabilities ensure Pro-Cam Services LLC. can efficiently process and quickly machine; angled holes, gears, sprockets, rollers, spanner flats on a bolt, cut straight lines at any angle, drill equidistant holes on a circular flange and much more!

Pro-Cam Services LLC. has true continues 4th-axis machining capabilities…There are a few advantages to Continuous Machining. First, you can machine shapes that would otherwise be impossible or very difficult. The closest thing possible without continuous machining would be to index as many positions as possible and use 3D contouring toolpaths to try to get the job done. This can be surprisingly effective, but is seldom as powerful as true Continuous Machining. Another advantage to Continuous Machining comes when profiling with a ballnose cutter. The ballnose has a weakness, which is that the closer you get to the tip, the slower the flutes are spinning. It sounds counter-intuitive, but just think of that tip as a series of concentric circles at different heights. The ones near the tip are smaller circles, their circumference is shorter, yet they’re spinning at exactly the same rpm as the bigger circles up higher. Hence, the tip moves slower. Conceptually, the exact tip isn’t really moving at all as it is a circle with zero radius.

Spline machined on the 4th-axis @ Pro-Cam Services LLC.

Large UHMW roller machined on the 4th-axis @ Pro-Cam Services LLC.

Over 1,000 holes drilled in one operation on the rotary table @ Pro-Cam Services LLC.

Precision Stainless Steel Details Machined at Pro-Cam Services LLC.

Tight tolerance precision stainless steel details machined to all around tolerances including flatness and parallelism of +/- .001 at Pro-Cam Services LLC. www.procamservices.com