Pro-Cam Services LLC. specializes in machining large aluminum plates for its customers from both 6061 and aluminum jig and fixture plate for the automation, OEM and a variety of other industries! Pro-Cam Services LLC. can machine aluminum plates as large as 80″X144″ featuring tight tolerances, drilled/tapped/reamed holes, 3D machining, complex or tricky features and most side holes! Pro-Cam Services LLC. has been machining big special fixture bases, special machine plates, special machine side walls, special gussets support beams, rails and much more for a wide variety of customers!

Pictured above fixture base plates machined from ATP5 ready for final inspection…than off to anodize and than off to the customer…manufactured at Pro-Cam Services LLC. for an OEM customer.

Pictured above is a platen machined on both sides from aluminum jig and fixture plate featuring tight tolerances and lots of machining… manufactured in batches of 40pc at Pro-Cam Services LLC. for an OEM customer.

Pictured above is large detail machined from a piece of 3″X38″X42″ 6061 aluminum featuring 3D machining on both sides manufactured in several different versions at Pro-Cam Services LLC. for an Automotive customer.

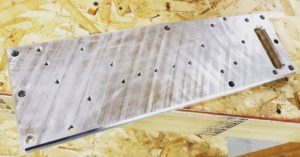

Pictured above is an exceptionally long detail machined from aluminum jig and fixture plate at Pro-Cam Services LLC. for an Automation customer.

Pictured above is an camera mount plate machined from aluminum jig and fixture plate at Pro-Cam Services LLC. for an Automation customer.

Pictured above special machine side walls machined from 1.5″ thick 6061 alum at Pro-Cam Services LLC. for an Automation customer.