CNC milling is a highly precise and efficient machining process that has revolutionized the manufacturing industry. It utilizes computer-controlled machines to carve out complex shapes and designs with incredible accuracy that might not be achievable through traditional machining methods.

One of the key factors determining the success of CNC milling operations is finding the right machinists who understand its intricate nuances. In this article, we’re sharing how to ensure that you’re working with qualified partners for your CNC milling service.

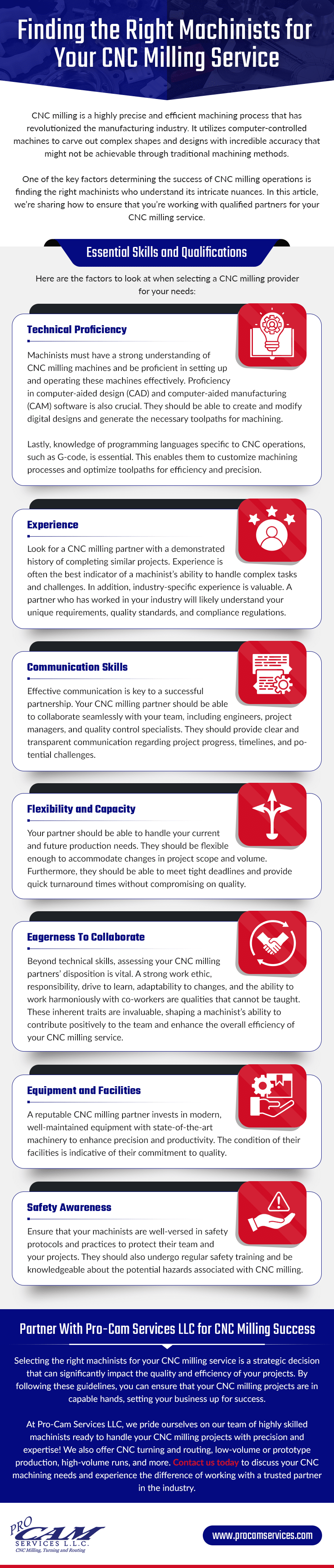

Essential Skills and Qualifications

Here are the factors to look at when selecting a CNC milling provider for your needs:

1. Technical Proficiency

Machinists must have a strong understanding of CNC milling machines and be proficient in setting up and operating these machines effectively. Proficiency in computer-aided design (CAD) and computer-aided manufacturing (CAM) software is also crucial. They should be able to create and modify digital designs and generate the necessary toolpaths for machining.

Lastly, knowledge of programming languages specific to CNC operations, such as G-code, is essential. This enables them to customize machining processes and optimize toolpaths for efficiency and precision.

2. Experience

Look for a CNC milling partner with a demonstrated history of completing similar projects. Experience is often the best indicator of a machinist’s ability to handle complex tasks and challenges. In addition, industry-specific experience is valuable. A partner who has worked in your industry will likely understand your unique requirements, quality standards, and compliance regulations.

3. Communication Skills

Effective communication is key to a successful partnership. Your CNC milling partner should be able to collaborate seamlessly with your team, including engineers, project managers, and quality control specialists. They should provide clear and transparent communication regarding project progress, timelines, and potential challenges.

4. Flexibility and Capacity

Your partner should be able to handle your current and future production needs. They should be flexible enough to accommodate changes in project scope and volume. Furthermore, they should be able to meet tight deadlines and provide quick turnaround times without compromising on quality.

5. Eagerness To Collaborate

Beyond technical skills, assessing your CNC milling partners’ disposition is vital. A strong work ethic, responsibility, drive to learn, adaptability to changes, and the ability to work harmoniously with co-workers are qualities that cannot be taught. These inherent traits are invaluable, shaping a machinist’s ability to contribute positively to the team and enhance the overall efficiency of your CNC milling service.

6. Equipment and Facilities

A reputable CNC milling partner invests in modern, well-maintained equipment with state-of-the-art machinery to enhance precision and productivity. The condition of their facilities is indicative of their commitment to quality.

7. Safety Awareness

Ensure that your machinists are well-versed in safety protocols and practices to protect their team and your projects. They should also undergo regular safety training and be knowledgeable about the potential hazards associated with CNC milling.

Partner With Pro-Cam Services LLC for CNC Milling Success

Selecting the right machinists for your CNC milling service is a strategic decision that can significantly impact the quality and efficiency of your projects. By following these guidelines, you can ensure that your CNC milling projects are in capable hands, setting your business up for success.

At Pro-Cam Services LLC, we pride ourselves on our team of highly skilled machinists ready to handle your CNC milling projects with precision and expertise! We also offer CNC turning and routing, low-volume or prototype production, high-volume runs, and more. Contact us today to discuss your CNC machining needs and experience the difference of working with a trusted partner in the industry.