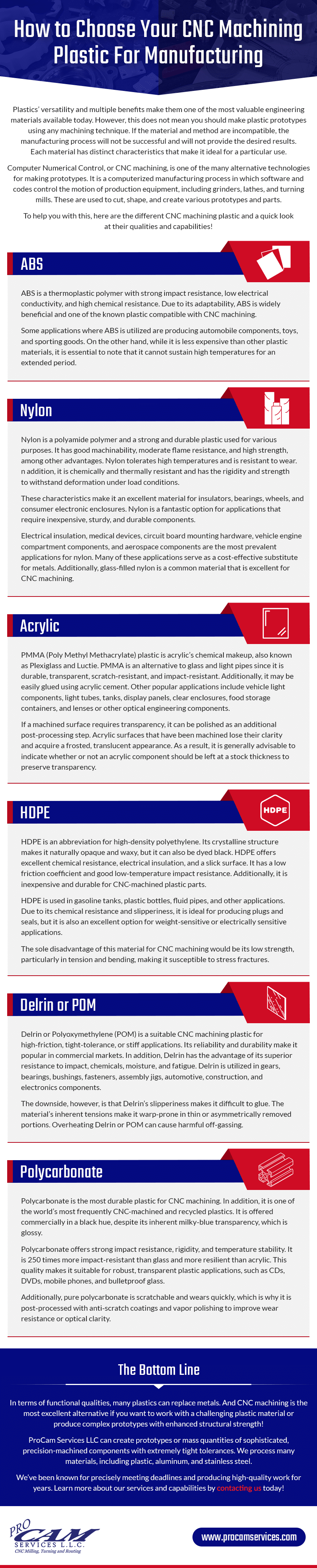

Plastics' versatility and multiple benefits make them one of the most valuable engineering materials available today. However, this does not mean you should make plastic prototypes using any machining technique. If the material and method are incompatible, the manufacturing process will not be successful and will not provide the desired results. Each material has distinct characteristics that make it ideal for a particular use.

Computer Numerical Control, or CNC machining, is one of the many alternative technologies for making prototypes. It is a computerized manufacturing process in which software and codes control the motion of production equipment, including grinders, lathes, and turning mills. These are used to cut, shape, and create various prototypes and parts.

If you use plastic material to design and manufacture parts, they should be CNC machined. There is a plethora of machinable plastic to select from for plastic machining, each with its properties and capabilities. CNC-machined plastic components make excellent prototypes and are readily available. Before machining, select the most suitable and optimal CNC machining plastic for your product.

To help you with this, here are the different CNC machining plastic and a quick look at their qualities and capabilities!

ABS

ABS is a thermoplastic polymer with strong impact resistance, low electrical conductivity, and high chemical resistance. Due to its adaptability, ABS is widely beneficial and one of the known plastic compatible with CNC machining.

Some applications where ABS is utilized are producing automobile components, toys, and sporting goods. On the other hand, while it is less expensive than other plastic materials, it is essential to note that it cannot sustain high temperatures for an extended period.

Nylon

Nylon is a polyamide polymer and a strong and durable plastic used for various purposes. It has good machinability, moderate flame resistance, and high strength, among other advantages. Nylon tolerates high temperatures and is resistant to wear. In addition, it is chemically and thermally resistant and has the rigidity and strength to withstand deformation under load conditions.

These characteristics make it an excellent material for insulators, bearings, wheels, and consumer electronic enclosures. Nylon is a fantastic option for applications that require inexpensive, sturdy, and durable components.

Electrical insulation, medical devices, circuit board mounting hardware, vehicle engine compartment components, and aerospace components are the most prevalent applications for nylon. Many of these applications serve as a cost-effective substitute for metals. Additionally, glass-filled nylon is a common material that is excellent for CNC machining.

Acrylic

PMMA (Poly Methyl Methacrylate) plastic is acrylic's chemical makeup, also known as

Plexiglass and

Luctie. PMMA is an alternative to glass and light pipes since it is durable, transparent, scratch-resistant, and impact-resistant. Additionally, it may be easily glued using acrylic cement. Other popular applications include vehicle light components, light tubes, tanks, display panels, clear enclosures, food storage containers, and lenses or other optical engineering components.

If a machined surface requires transparency, it can be polished as an additional post-processing step. Acrylic surfaces that have been machined lose their clarity and acquire a frosted, translucent appearance. As a result, it is generally advisable to indicate whether or not an acrylic component should be left at a stock thickness to preserve transparency.

HDPE

HDPE is an abbreviation for high-density polyethylene. Its crystalline structure makes it naturally opaque and waxy, but it can also be dyed black. HDPE offers excellent chemical resistance, electrical insulation, and a slick surface. It has a low friction coefficient and good low-temperature impact resistance. Additionally, it is inexpensive and durable for CNC-machined plastic parts.

HDPE is used in gasoline tanks, plastic bottles, fluid pipes, and other applications. Due to its chemical resistance and slipperiness, it is ideal for producing plugs and seals, but it is also an excellent option for weight-sensitive or electrically sensitive applications.

The sole disadvantage of this material for CNC machining would be its low strength, particularly in tension and bending, making it susceptible to stress fractures.

Delrin or POM

Delrin or Polyoxymethylene (POM) is a suitable CNC machining plastic for high-friction, tight-tolerance, or stiff applications. Its reliability and durability make it popular in commercial markets. In addition, Delrin has the advantage of its superior resistance to impact, chemicals, moisture, and fatigue. Delrin is utilized in gears, bearings, bushings, fasteners, assembly jigs, automotive, construction, and electronics components.

The downside, however, is that Delrin's slipperiness makes it difficult to glue. The material's inherent tensions make it warp-prone in thin or asymmetrically removed portions. Overheating Delrin or POM can cause harmful off-gassing.

Polycarbonate

Polycarbonate is the most durable plastic for CNC machining. In addition, it is one of the world's most frequently CNC-machined and recycled plastics. It is offered commercially in a black hue, despite its inherent milky-blue transparency, which is glossy.

Polycarbonate offers strong impact resistance, rigidity, and temperature stability. It is 250 times more impact-resistant than glass and more resilient than acrylic. This quality makes it suitable for robust, transparent plastic applications, such as CDs, DVDs, mobile phones, and bulletproof glass.

Additionally, pure polycarbonate is scratchable and wears quickly, which is why it is post-processed with anti-scratch coatings and vapor polishing to improve wear resistance or optical clarity.

The Bottom Line

In terms of functional qualities, many plastics can replace metals. And CNC machining is the most excellent alternative if you want to work with a challenging plastic material or produce complex prototypes with enhanced structural strength!

ProCam Services LLC can create prototypes or mass quantities of sophisticated, precision-machined components with extremely tight tolerances. We process many materials, including plastic, aluminum, and stainless steel.

We've been known for precisely meeting deadlines and producing high-quality work for years. Learn more about our services and capabilities by

contacting us today!